| | Published September 14th, 2011

| Cutting Tree Problems Down to Size

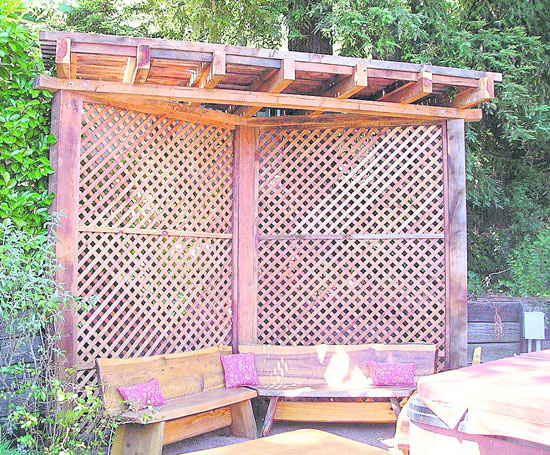

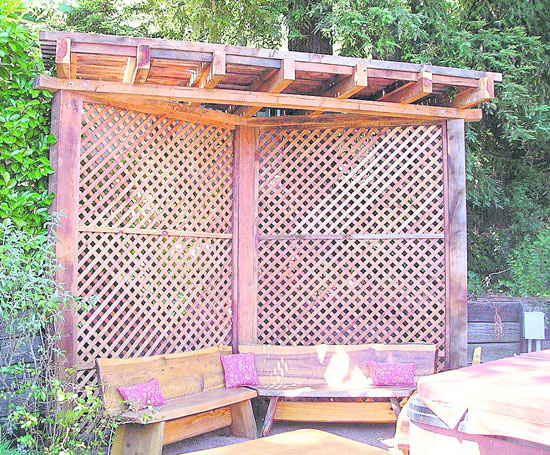

| | Cathy Dausman |  | | A charming seating area, fashioned from locally felled wood, is inviting in Victor Ghavamzadeh's yard. Photos Cathy Dausman

|

Lamorinda may not have "gold in them thar hills," but there is plenty of Urban Lumber. That is the term Victor Ghavamzadeh uses to describe on-site recycling of trees and wood felled by tree cutting companies. Ghavamzadeh, who owns East Bay Tree Service, says on-site wood milling is easier on the environment. Not having to haul away trees means using less gas and fewer trucks and resources for the project. It also presents the homeowner with a variety of options. Depending on the wood, the freshly cut trees may yield bark chips, firewood, landscaping steps or slab lumber milled on site.

Much of Lamorinda was barren hillside until the 1960's. Then the state suggested local homeowners plant Monterey Pines for erosion control. The seedlings were sold for pennies apiece. Fast forward forty years, and those same trees have matured. Now homeowners are taking them out.

Much of Lamorinda was barren hillside until the 1960's. Then the state suggested local homeowners plant Monterey Pines for erosion control. The seedlings were sold for pennies apiece. Fast forward forty years, and those same trees have matured. Now homeowners are taking them out.

Soft woods like Monterey Pine are unsuitable for milling, but can easily be chipped or mulched. The homeowner gets instant free ground cover, and the same trees which block sunlight or threaten to damage nearby real estate if they topple are born again.

Soft woods like Monterey Pine are unsuitable for milling, but can easily be chipped or mulched. The homeowner gets instant free ground cover, and the same trees which block sunlight or threaten to damage nearby real estate if they topple are born again.

Hardwoods like walnut can be cut into planks and posts, the kind you'd "never be able to buy" at a lumber yard, Ghavamzadeh says. Using a portable mill, urban lumber can easily be cut into any size within machine limitations.

Hardwoods like walnut can be cut into planks and posts, the kind you'd "never be able to buy" at a lumber yard, Ghavamzadeh says. Using a portable mill, urban lumber can easily be cut into any size within machine limitations.

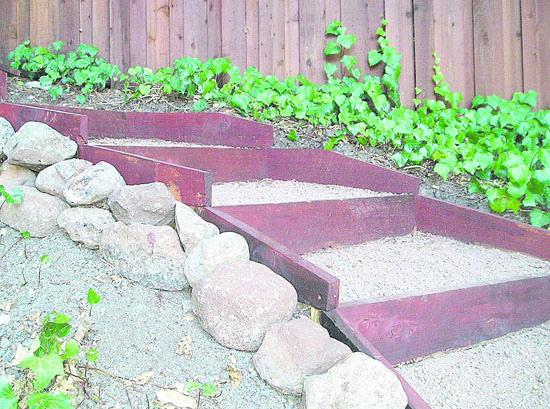

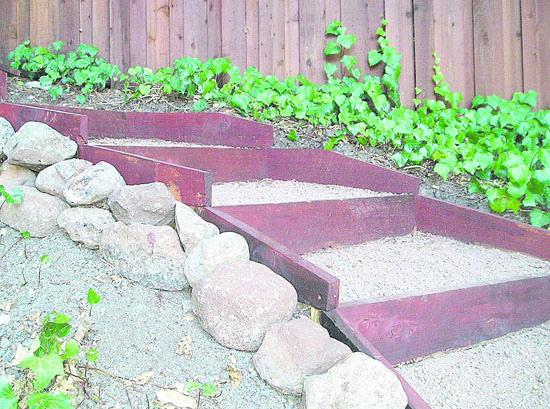

Ghavamzadeh's house holds the spoils of his business, in the form of furniture he has made from locally felled wood. His oversized dining room table is built of redwood and came from a work project in Danville. "You'd never be able to buy it," he says of the table. His backyard boasts a redwood deck and arbors, fencing, benches and steps with redwood retaining walls. "I remember the jobs [each wood project came from]," he says.

Ghavamzadeh's house holds the spoils of his business, in the form of furniture he has made from locally felled wood. His oversized dining room table is built of redwood and came from a work project in Danville. "You'd never be able to buy it," he says of the table. His backyard boasts a redwood deck and arbors, fencing, benches and steps with redwood retaining walls. "I remember the jobs [each wood project came from]," he says.

Ghavamzadeh adds that he's toyed with buying his own equipment and milling the lumber himself, but decided instead just to facilitate between his tree service and a Martinez mill which specializes in custom cutting high quality slabs and planks.

Ghavamzadeh adds that he's toyed with buying his own equipment and milling the lumber himself, but decided instead just to facilitate between his tree service and a Martinez mill which specializes in custom cutting high quality slabs and planks.

On-site milling can be done with portable equipment, however. Earlier this summer, a Lamorinda family removed a 145 foot tall, 3 foot diameter Sequoia from their property. With its weakened root system, the 50 year old tree threatened to damage the house if it fell. It was first topped, and then removed in sections cut in 8 foot lengths.

On-site milling can be done with portable equipment, however. Earlier this summer, a Lamorinda family removed a 145 foot tall, 3 foot diameter Sequoia from their property. With its weakened root system, the 50 year old tree threatened to damage the house if it fell. It was first topped, and then removed in sections cut in 8 foot lengths.

Redwood too soft to make furniture makes great fence lumber. This particular tree, however, was furniture grade-- it was old growth redwood-Sequoia Giganticus.

Redwood too soft to make furniture makes great fence lumber. This particular tree, however, was furniture grade-- it was old growth redwood-Sequoia Giganticus.

The family didn't want the wood, but Martin O'Gorman did. O'Gorman first learned it was available on Craigslist. The family had promised the wood to a chainsaw artist from Petaluma, but O'Gorman kept after the owners. When the first woodworker failed to show, the owners allowed him to reap the harvest.

The family didn't want the wood, but Martin O'Gorman did. O'Gorman first learned it was available on Craigslist. The family had promised the wood to a chainsaw artist from Petaluma, but O'Gorman kept after the owners. When the first woodworker failed to show, the owners allowed him to reap the harvest.

"This [tree] is history," he says, admiring his windfall. "I'm pretty happy to be here." He must have been-- O'Gorman, who works in the construction trade and makes custom cabinetry and furniture as a hobby, drove three hours from Lake Tahoe just to get it. In two days, using a 30 horsepower portable "Alaskan mill" chainsaw with a five-foot blade, O'Gorman sliced the larger stumps into 3-inch thick slabs showing beautiful colorations from brown to red. The trunk showed low moisture and seemed free of termites.

"This [tree] is history," he says, admiring his windfall. "I'm pretty happy to be here." He must have been-- O'Gorman, who works in the construction trade and makes custom cabinetry and furniture as a hobby, drove three hours from Lake Tahoe just to get it. In two days, using a 30 horsepower portable "Alaskan mill" chainsaw with a five-foot blade, O'Gorman sliced the larger stumps into 3-inch thick slabs showing beautiful colorations from brown to red. The trunk showed low moisture and seemed free of termites.

The chainsaw worked like a giant cheese slicer, and since the wood was soft, each pass took less than ten minutes to complete. But that is only the first step. The wood will need to be cured -- stored flat in a cool, dry place-for many months. O'Gorman says a finished 4 by 8 foot redwood slab-likely destined to be a table top-- has a retail value of $1,000. A comparable Madrone wood slab would be worth $6,000. Noting someone else's errant chainsaw marks in the burl wood (stump), O'Gorman shook his head sadly. Left untouched, he says, that would have been the real prize.

The chainsaw worked like a giant cheese slicer, and since the wood was soft, each pass took less than ten minutes to complete. But that is only the first step. The wood will need to be cured -- stored flat in a cool, dry place-for many months. O'Gorman says a finished 4 by 8 foot redwood slab-likely destined to be a table top-- has a retail value of $1,000. A comparable Madrone wood slab would be worth $6,000. Noting someone else's errant chainsaw marks in the burl wood (stump), O'Gorman shook his head sadly. Left untouched, he says, that would have been the real prize.

It seems the prize is not what is in the Lamorinda hills, but what grows upon it.

It seems the prize is not what is in the Lamorinda hills, but what grows upon it.

Even today, an area once known for its redwoods and old growth lumber continues to "give back" to the landowners, if only they know how to look for it.

Even today, an area once known for its redwoods and old growth lumber continues to "give back" to the landowners, if only they know how to look for it.

|

| | Raw materials: a redwood tree is felled in Lamorinda

|  | | Ghavamzadeh's landscaping steps use recycled redwood as retaining walls.

|  | | Wood worker Martin O'Gorman cuts felled redwood into slabs. He'll take the slabs to cure before making them into table tops.

Photos Eric Dausman

|  | |

| | | | | Advertisement | | |

| | | print story

Before you print this article, please remember that it will remain in our archive for you to visit anytime.

download pdf

(use the pdf document for best printing results!) | | | Comments | | |

| | | | | | | | | | | | | | | | |